Also, check out our Infrared RD Handbook.

Maximize Performance with Teledyne FLIR R&D Science Cameras

Unlock the full potential of your testing and data capture with Teledyne FLIR R&D Science cameras, designed to meet the demands of the new FIA 2026 regulations for Formula 1. Our cutting-edge technology ensures precise, reliable data collection, allowing you to enhance performance, efficiency, and innovation in your race engineering.

Key Benefits:

- Advanced Data Precision: Capture detailed thermal data with unparalleled accuracy, essential for complying with the more stringent FIA 2026 regulations.

- Enhanced Performance Analysis: Leverage high-speed, high-resolution imaging to analyse critical performance metrics and optimize your vehicle’s performance.

- Innovative Engineering Support: Our cameras support the latest innovations in vehicle design, helping you stay ahead in the fast-evolving world of Formula 1.

- Comprehensive Testing Solutions: From aerodynamic testing to thermal management, our cameras provide comprehensive solutions for all your R&D needs.

Stay ahead of the competition and meet the future of Formula 1 head-on with Teledyne FLIR R&D Science cameras. Explore how our advanced imaging solutions can elevate your performance to new heights.

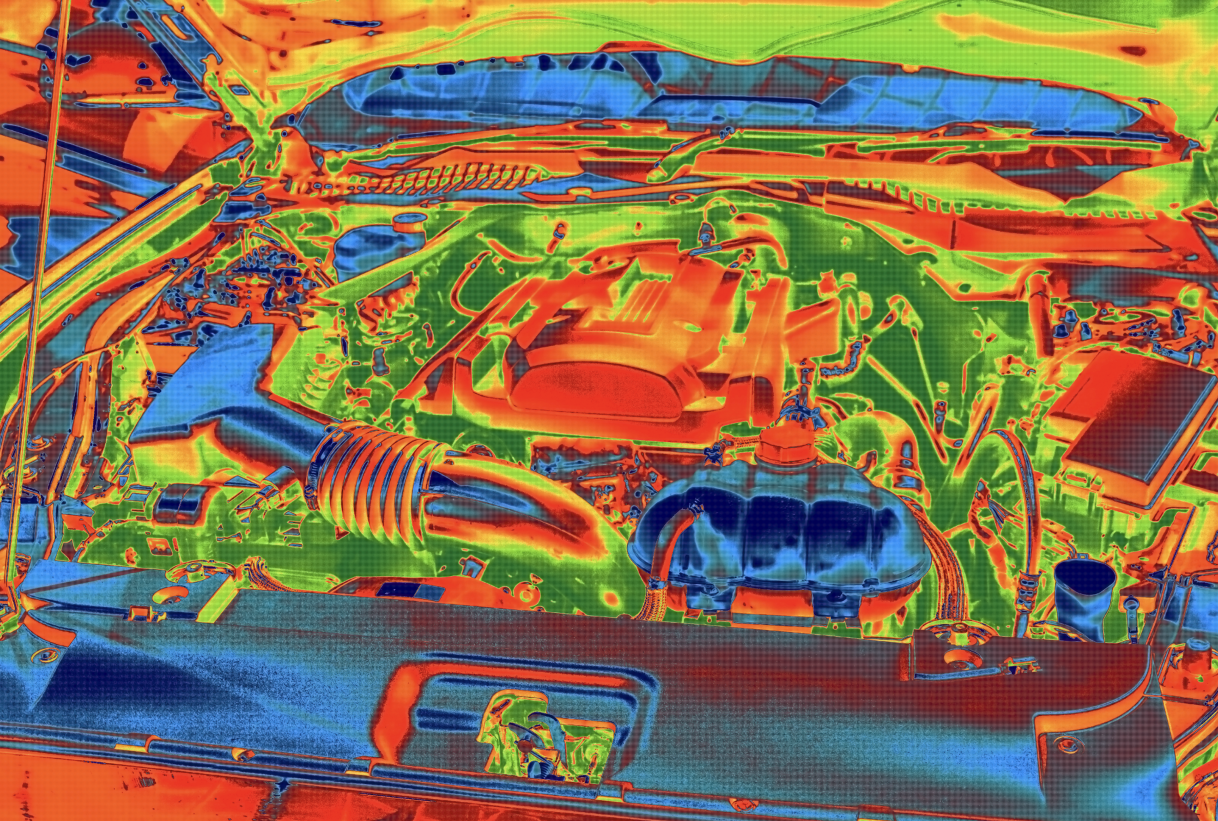

The image shows a thermal overview of your engines heat performance, providing real-time information on the efficiency of your

Understanding the 2026 Formula 1 Power Unit Regulations

The FIA’s 2026 power unit regulations aim to revolutionize Formula 1 with a focus on sustainability, efficiency, and enhanced performance. Key changes include:

- Increased Electrical Power: The new regulations double the electrical power output, emphasizing hybrid technology.

- Sustainable Fuels: All power units must use 100% sustainable fuels.

- Cost Management: There are stricter cost controls to ensure financial sustainability.

- Enhanced Energy Recovery: Improved Energy Recovery Systems (ERS) to increase efficiency.

How Teledyne FLIR Cameras Assist with Compliance

Our Teledyne FLIR R&D Science cameras are perfectly suited to help teams comply with and excel under these new regulations:

- Battery Testing: With increased electrical power, battery performance and safety are critical. Our cameras provide precise thermal imaging to monitor and optimize battery temperatures, ensuring reliability and performance.

- R&D Support: The shift towards sustainable fuels and enhanced ERS requires extensive research and development. Our high-resolution thermal cameras help engineers detect inefficiencies, optimize designs, and ensure components meet the new standards.

- Energy Density Testing (EDT): Accurate energy density testing is crucial under the new regulations. Our cameras offer detailed thermal analysis, helping teams maximize energy efficiency and maintain competitive edge.

Harness the power of Teledyne FLIR’s advanced imaging technology to meet the 2026 FIA regulations with confidence, ensuring your team stays ahead in the evolving landscape of Formula 1.

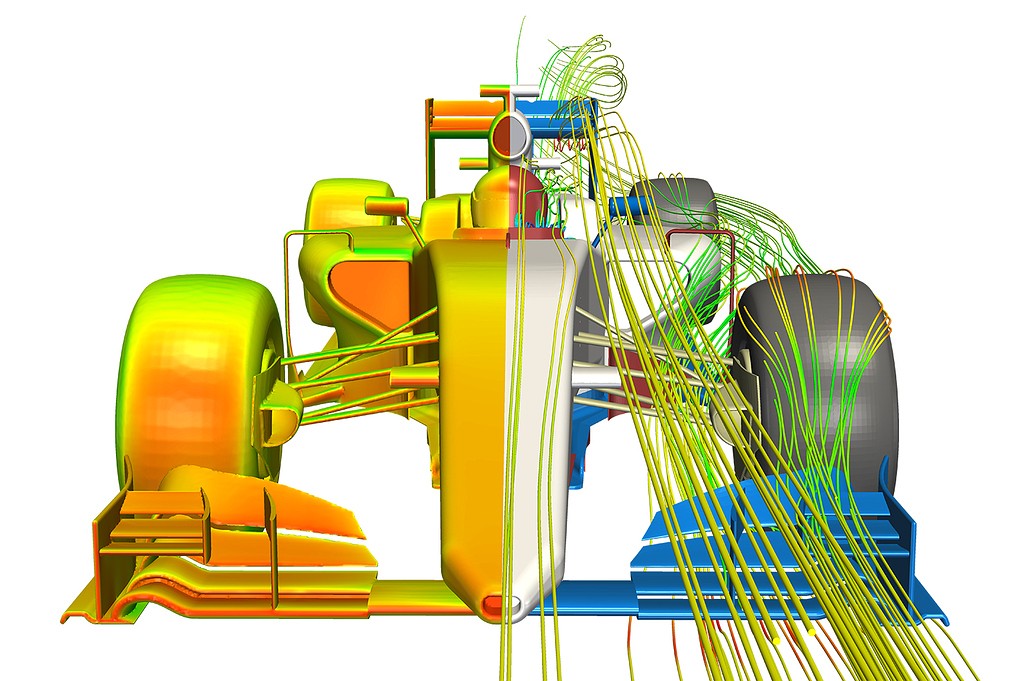

Understanding the 2026 Formula 1 Aerodynamic Regulations

The FIA’s 2026 aerodynamic regulations introduce significant changes to enhance racing dynamics and sustainability. Key aspects include:

- Simplified Designs: To reduce turbulence and improve overtaking opportunities.

- Enhanced Downforce: Changes to the car’s aerodynamics to ensure higher levels of downforce while maintaining efficient airflow.

- Sustainability Focus: Materials and design adjustments to align with environmental goals.

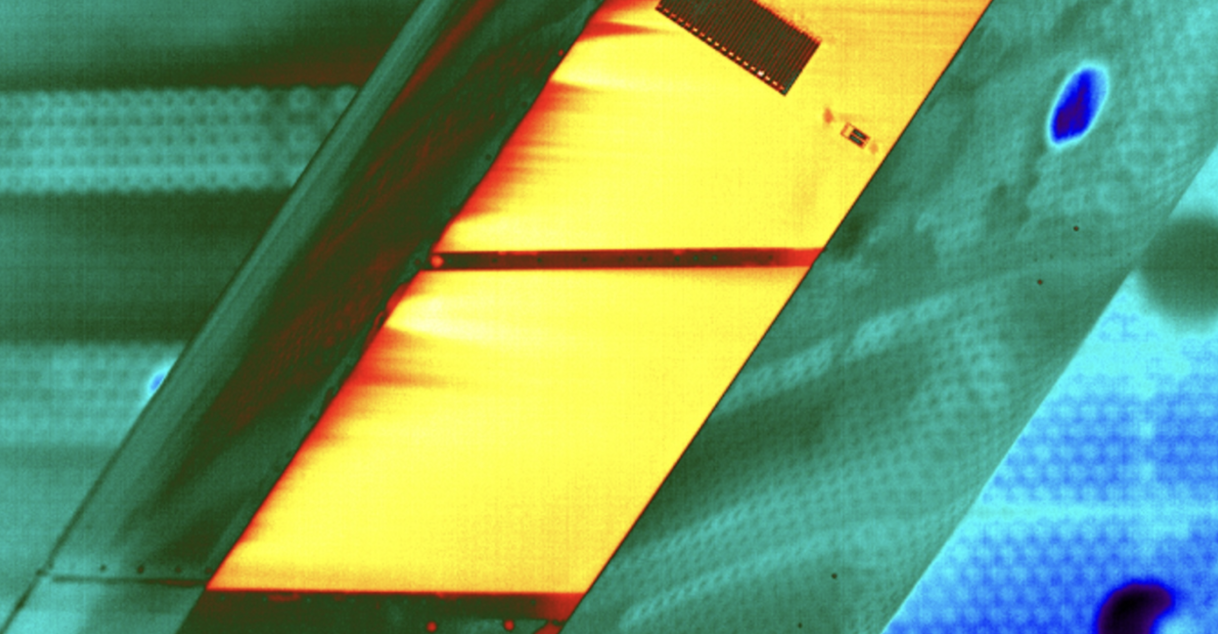

How Teledyne FLIR Cooled Science Cameras Assist with Aerodynamics Testing

Teledyne FLIR’s cooled science cameras offer critical advantages for F1 teams adapting to these new aerodynamic regulations:

- Precision Thermal Imaging: Our cameras provide highly accurate thermal images, enabling teams to detect subtle changes in airflow and heat distribution across the vehicle.

- Detailed Flow Visualization: Capture high-resolution images that reveal the effects of aerodynamic adjustments in real-time, helping engineers refine designs for optimal downforce and reduced drag.

- Material Performance Analysis: Assess the thermal properties of new sustainable materials, ensuring they meet performance standards without compromising aerodynamic efficiency.

- Enhanced Testing Accuracy: With our advanced imaging technology, teams can conduct comprehensive aerodynamic tests, ensuring compliance with FIA regulations and achieving superior performance.

Leverage Teledyne FLIR’s cooled science cameras to excel under the new 2026 aerodynamic regulations, ensuring your F1 team stays at the forefront of innovation and competitiveness.

The image shows laminar flow over a composite wing. Thermal imaging allows for real-time imaging of aerodynamic performance for rapid car design.

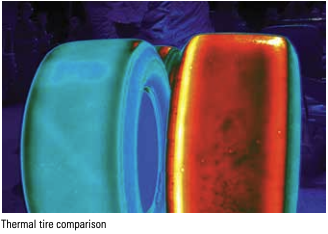

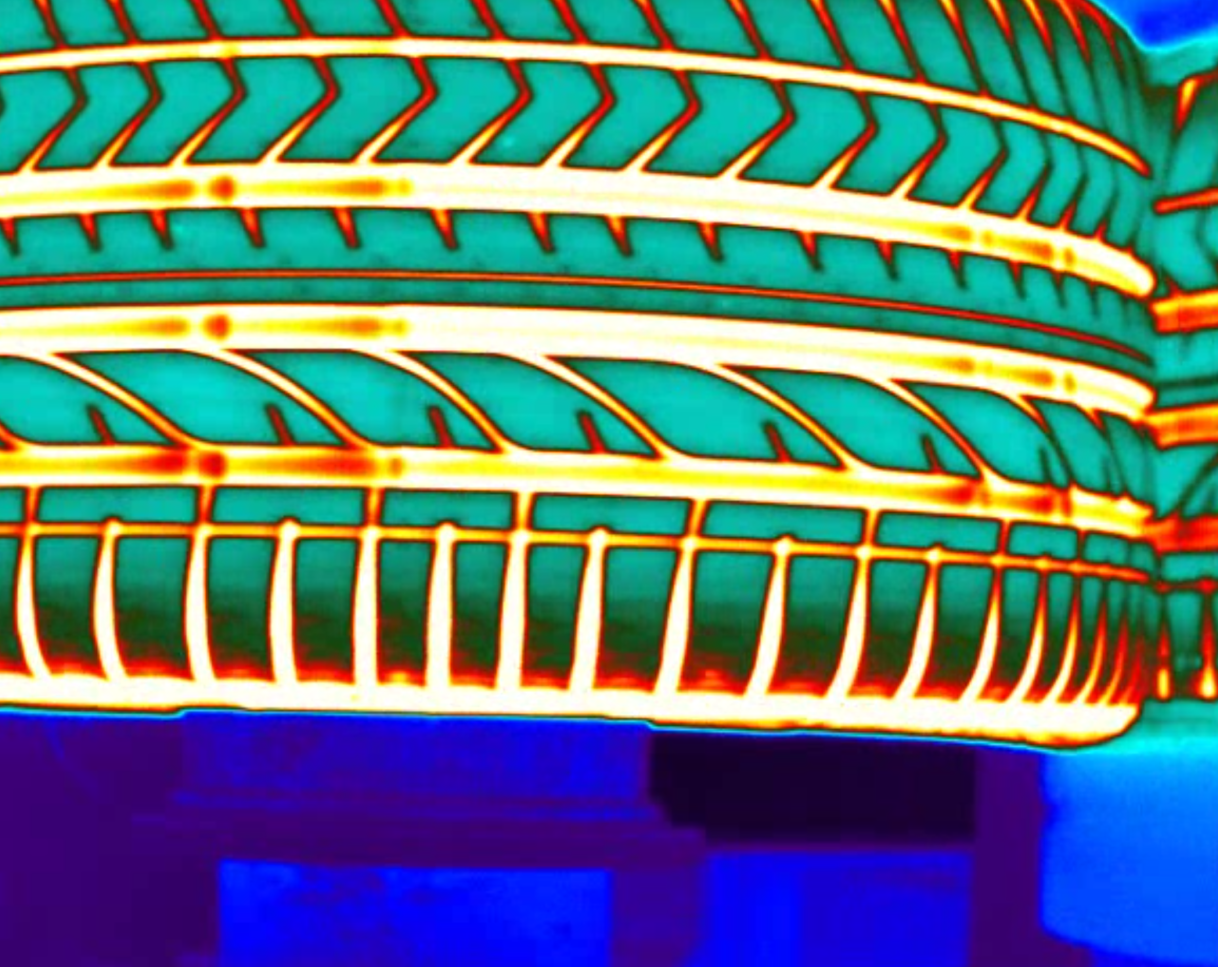

Real-time Thermal imaging can show the heat created by the tyre’s friction against the road surface, helping to understand car setup and aerodynamic performance.

Understanding the 2026 Formula 1 Tyre Management Regulations

The FIA’s 2026 technical regulations for Formula 1 introduce new guidelines aimed at improving tyre management. These regulations focus on enhancing tyre durability, performance, and sustainability. Key elements include:

- Durability: Emphasis on tyre compounds that offer greater longevity during races.

- Performance: Optimizing tyre performance to maintain grip and efficiency throughout varying conditions.

- Sustainability: Development of eco-friendly tyre materials and manufacturing processes.

How Teledyne FLIR Cooled Science Cameras Assist with Tyre Management

Teledyne FLIR’s cooled R&D science cameras provide essential support for F1 teams adapting to these tyre management regulations:

- Thermal Performance Monitoring: Our cameras deliver precise thermal imaging to monitor tyre temperatures in real-time, helping teams understand heat distribution and its impact on tyre wear and performance.

- Compound Analysis: Detailed thermal analysis assists in evaluating different tyre compounds, ensuring they meet the durability and performance standards set by the new regulations.

- Efficiency Optimization: By capturing high-resolution thermal data, teams can optimize tyre usage strategies, improving overall efficiency and race performance.

- Data-Driven Decisions: Our advanced imaging technology provides comprehensive data, enabling teams to make informed decisions on tyre selection, pressure settings, and race tactics.

Utilize Teledyne FLIR’s cooled R&D science cameras to enhance tyre management, ensuring compliance with the 2026 regulations and achieving superior performance on the track.

Meet the kit

Teledyne FLIR, a leader in thermal imaging and infrared technology, specializes in advanced sensing solutions for various applications. Renowned for their innovative products, they provide critical tools for surveillance, industrial inspection, and environmental monitoring. Their comprehensive range includes thermal cameras, sensors, and integrated systems, enabling users to see in complete darkness, monitor temperature changes, and detect potential issues before they escalate.

Serving sectors such as defence, public safety, and industrial operations, Teledyne FLIR’s cutting-edge technologies enhance situational awareness, safety, and efficiency. Committed to excellence and innovation, they continue to push the boundaries of what is possible in thermal imaging and sensing.

FLIR X and A Series

Advanced Thermal Systems

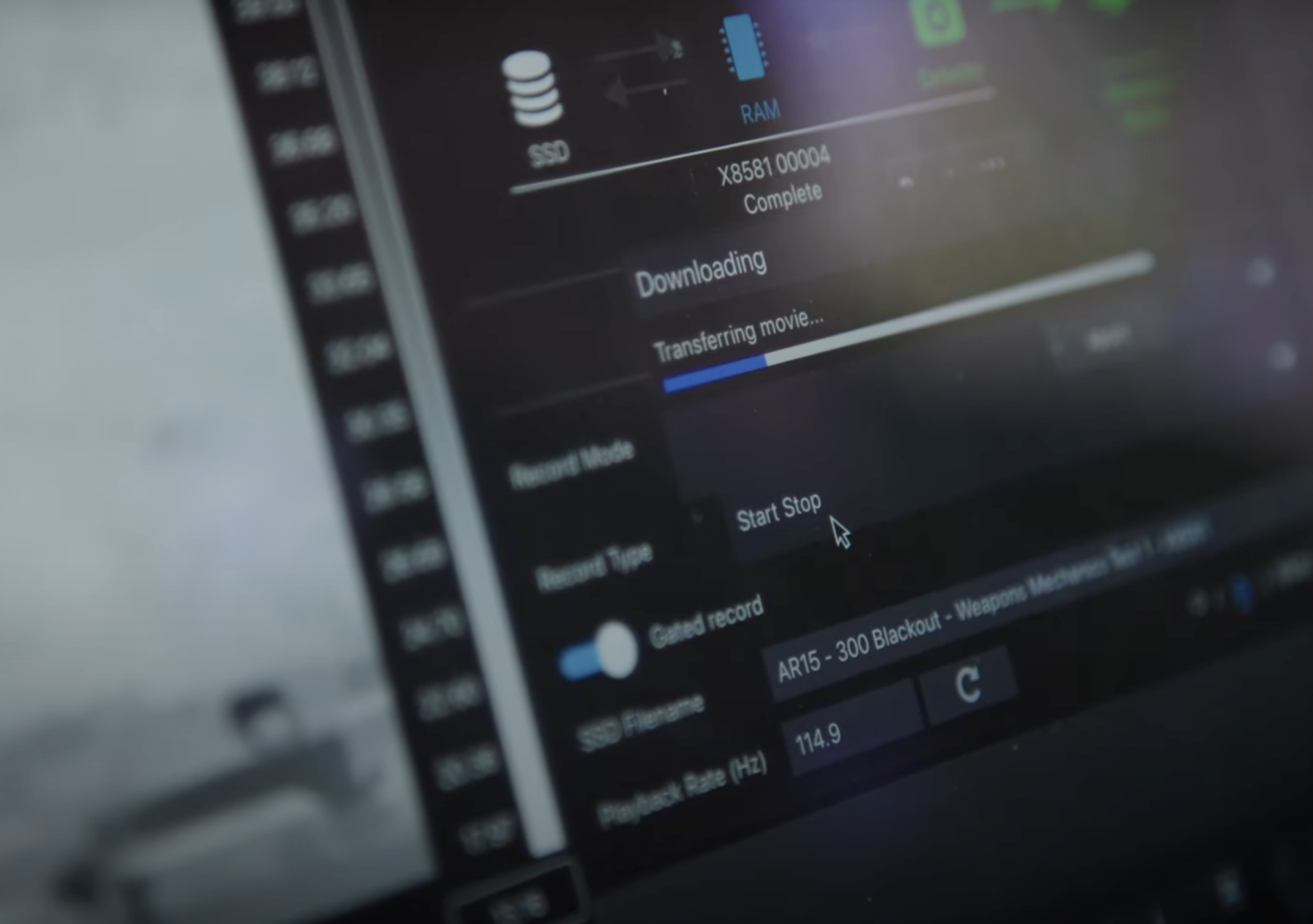

The Teledyne FLIR X-Series cameras, particularly the new models such as the X6980-HS and X8580-HS, are high-performance thermal imaging solutions designed for advanced research and development applications. These cameras cover both mid-wave infrared (MWIR) and long-wave infrared (LWIR) spectrums, offering superior imaging capabilities.

The high-speed series (HS) models are equipped with 10GigE and CoaXPress interfaces for rapid data transfer and include a removable NVMe SSD for lossless recording of critical thermal events. Ideal for detailed thermal analysis, these cameras support synchronization with multiple sensors using FLIR Research Studio software, enhancing their utility in complex R&D environments.

FLIR A700sc

UnCooled System

The FLIR A400/A700 Science Kits are advanced thermal imaging solutions for scientific research and development. These kits provide high-resolution thermal cameras and powerful software for precise temperature measurement and analysis. Ideal for laboratory and industrial applications, they enable users to capture detailed thermal data and conduct in-depth analysis. Features include spot and area measurements, radiometric streaming, and customizable configurations to suit specific research needs. The FLIR A400/A700 Science Kits support real-time data collection and integration with third-party analysis tools. They are invaluable for enhancing research capabilities and ensuring accurate, reliable results in various scientific disciplines.

FLIR A6301sc

New Cooled System

FLIR A6301 Advanced Thermal Camera offer engineers and system integrators the best and most advanced thermal camera for Process Control, Monitoring and Quality Assurance. Its industry-leading 27,000-hour cryocooler lifetime maximizes camera uptime for consistent production throughput, while minimizing cost through planned maintenance. Its fast integration times improves yield, through-put time, costs, while ensuring consistent quality. This cooled camera platform provides a streamlined solution for accurate temperature measurement. The Standard kit includes a FLIR A6301 Advanced Thermal Camera, accessories, and 17 mm, 24 mm, or 50 mm lens.

Research Studio

Advanced Software for Camera Control and data processing

FLIR Research Studio is designed to work the way you do, providing robust recording and analysis capabilities with an intuitive user interface for various research & development applications. This premium, advanced thermal analysis software offers a simplified workflow for displaying, recording, and evaluating data from multiple FLIR cameras simultaneously – allowing you to interpret and understand critical information quickly.

FLIR Research Studio also features multi-language and multi-platform support (Windows, MacOS, Linux) to improve collaboration between team members, increase efficiency, and help reduce the potential for misinterpretation due to poor translations.

The example below shows Research Studio plotting a temperature through time plot based on several points of interest in the captured recording. This data can also be exported for further analysis.

Contact Us

Here is a precise what3words address, made of 3 random words. Every 3-metre square in the world has its own unique what3words address.

You’ve read the story, seen some of our products, if you can let us know what you’re looking for, we’ll see how we can help.

Please note visits are by appointment only.

The Macintosh Consultancy Ltd ( for Thermal Vision Research Ltd )

2530 The Quadrant

Aztec West

Bristol

BS32 4AQ

T: 03332004667

E: matthew@thermalvisionresearch.co.uk

W: www.thermalvisionresearch.co.uk

Based in the South West of the UK we can easily travel to all parts of the UK. Bristol Airport is only 30min away providing quick connection to places such as Glasgow and Edinburgh.

by Car

by Train

by Air

Precision in Motion — Thermal Imaging Meets Performance What if you could see performance? Not just a guess. At TVI (Thermal Vision Industrial), we specialise in capturing what the...

Precision in Motion — Thermal Imaging Meets Performance What if you could see performance? Not just a guess. At TVI (Thermal Vision Industrial), we specialise in capturing what the...

Online Shop Premium X-Series Advanced A-Series Highend UnCooled Buy Online Entry Level Buy Online Software Buy Online FLIR Systems R&D cameras contribute to aerodynamic research...

Online Shop Premium X-Series Advanced A-Series Highend UnCooled Buy Online Entry Level Buy Online Software Buy Online FLIR Systems R&D cameras contribute to aerodynamic research...